Underground Charging and Blasting Vehicles RTB (Ruda Truck Blasting)

Underground Charging and Blasting Vehicles RTB (Ruda Truck Blasting)

The RTB underground charging and blasting vehicles are provided for production, transportation and mechanized charging the drilled blasting holes with the emulsion-type explosive which is made directly at the mine face by mixing few neutral components. The explosive is produced and charged by means of the modular mixing and charging unit.

The RTB vehicle is dedicated to underground galleries being 1,7 up to 4,5 m high and minimum 4,2 m wide. It may be used to charge the drilled holes up to 5 m long, providing at the same time 3 seats for the workers (1 operator + 2 blasting officers), along with the mixing – charging module up to 1 cu.m capacity.

These charging and blasting vehicles are made for non-coal and non-methane underground mines. The operator cabins are made according to the highest safety standards meeting the 60kJ FOPS with optional air-conditioning and filtration. They are equipped to work in extremely tough environmental conditions, having excellent tramming features thanks to big attack angles, undercarriage clearance and the main hinge of two degrees of freedom (no cradle). Their classic power train is composed of the diesel engine, torque converter, transmission and axles with built-in multi-plate brakes.

The vehicles are available in different versions adapted to specific requirements of the customers.

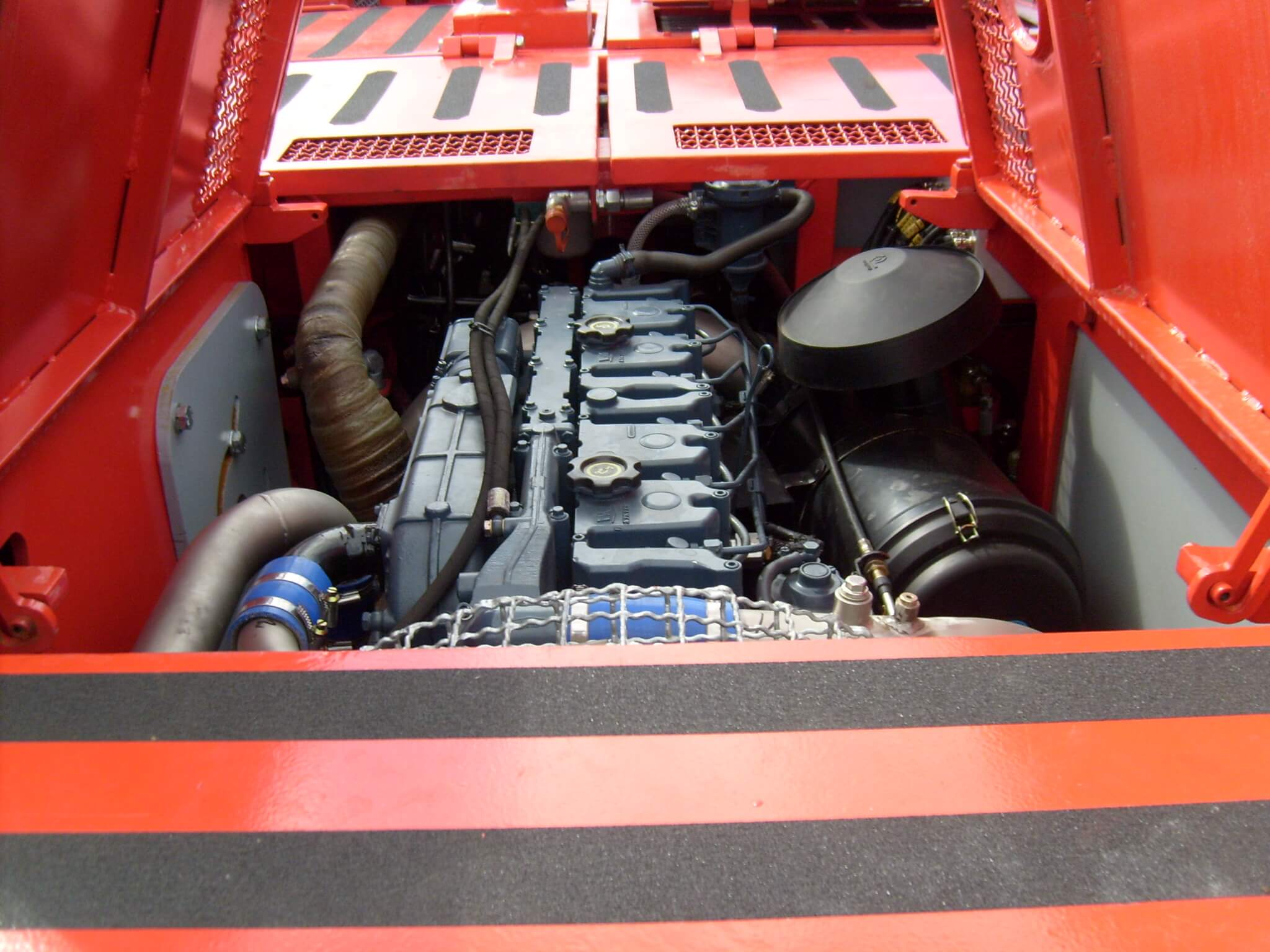

The high-end control desk has a display and two cameras and a mirror system make it easier for the operator to move the machine. SWS-RTB is equipped as standard with a Mercedes diesel engine.

The blasting operator’s control panel is placed in the FOPS60kJ safe cabin. The operator, despite the low overall size of the machine, has a comfortable seat for comfortable work throughout the entire shift.

The unique, patented solution enables easy service access to the engine. Optionally, SWS-RTB is equipped with air-conditioned cabins.